Gear simulation

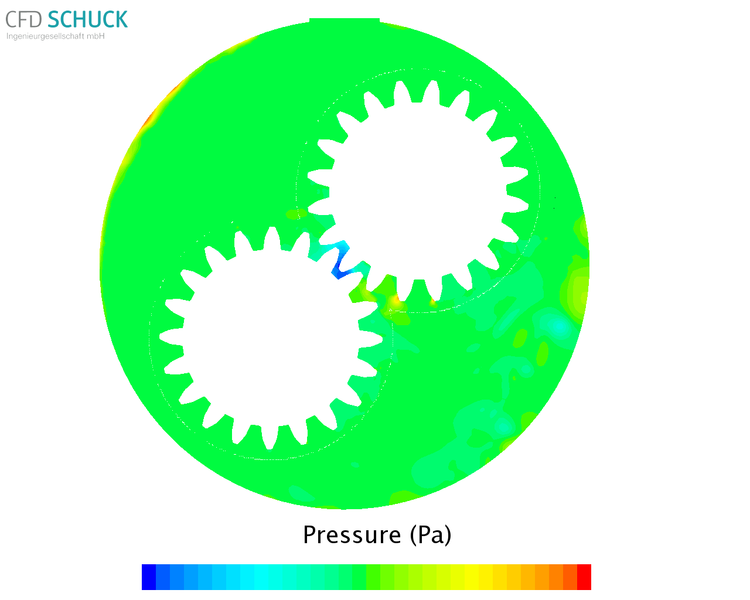

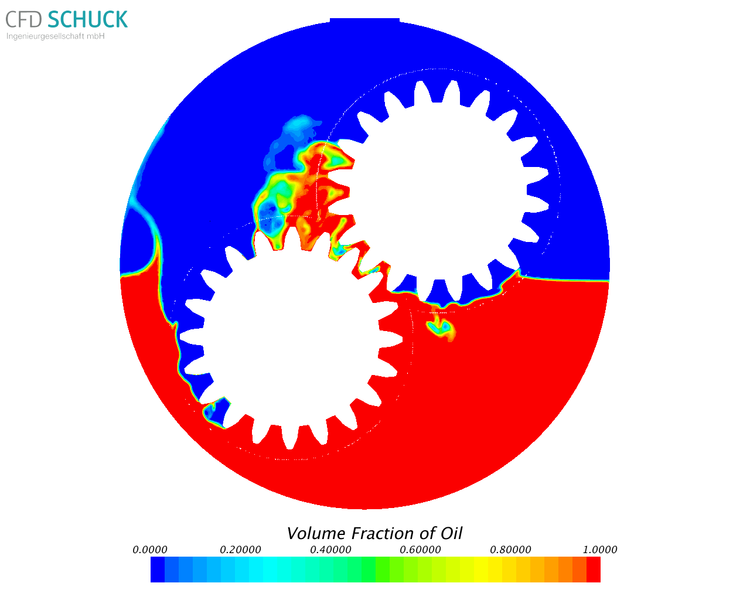

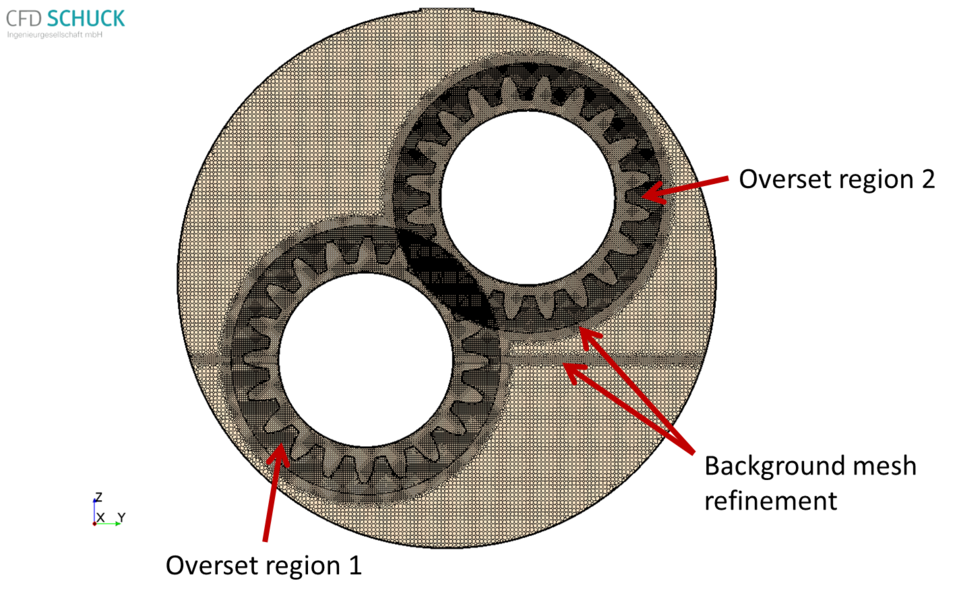

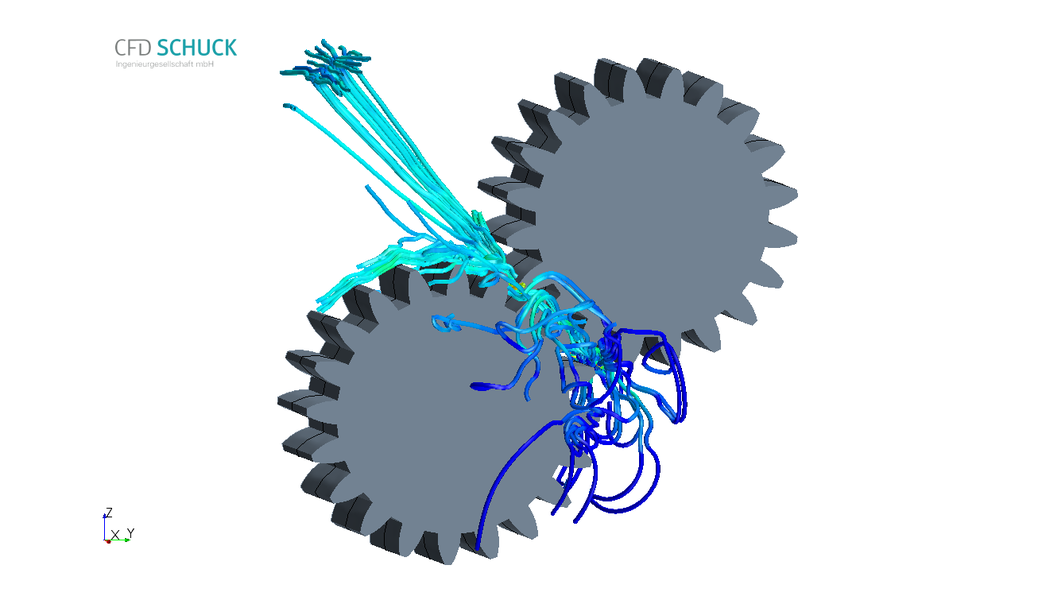

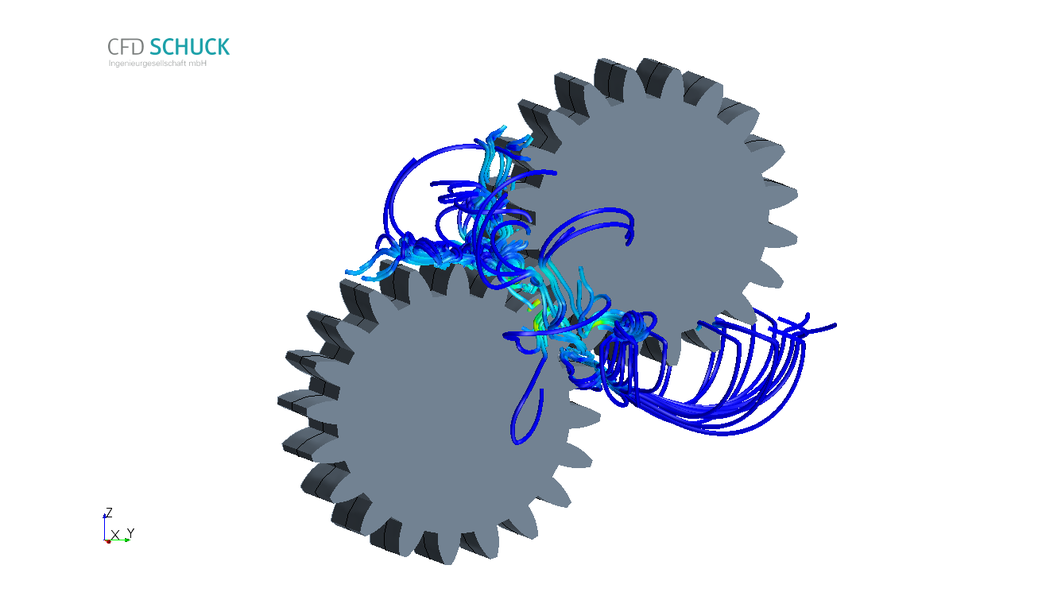

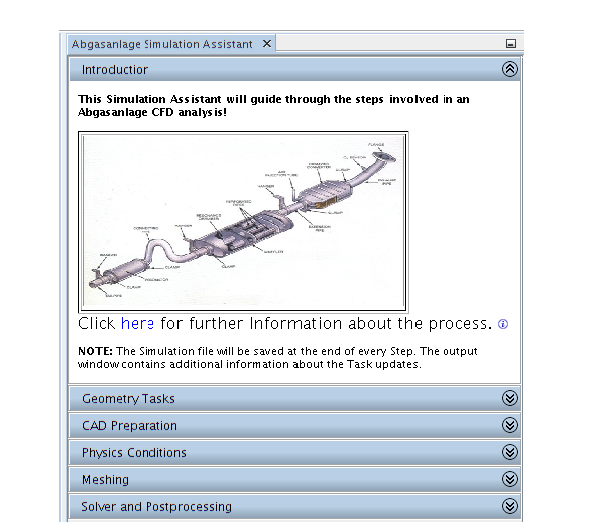

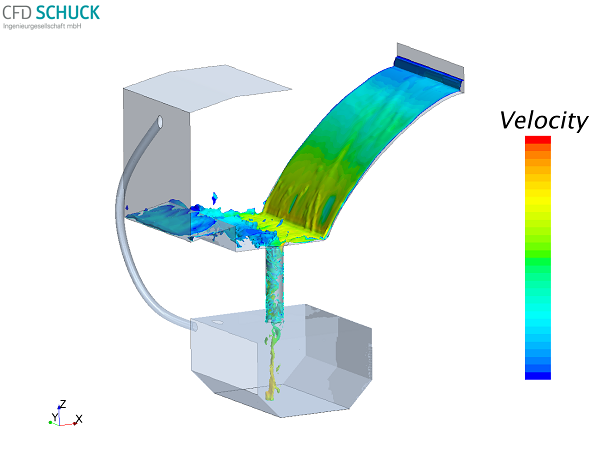

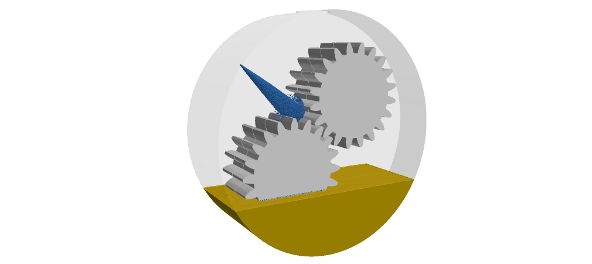

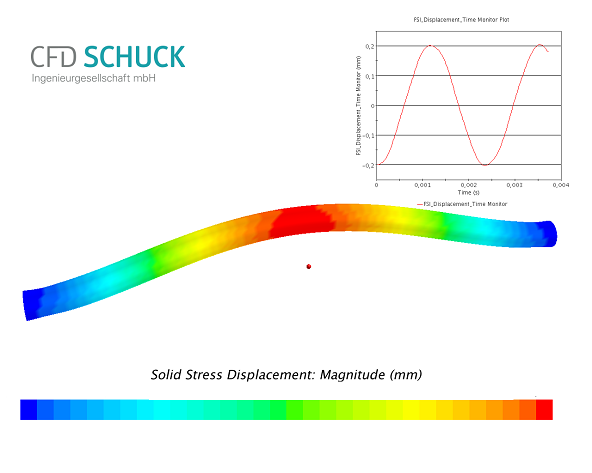

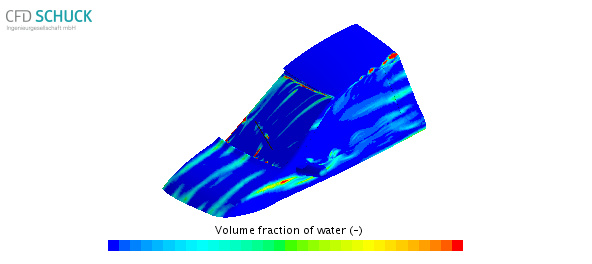

Problems which arise when gear lubrication becomes insufficient are well known by every bicycle rider as well as car driver. Replacement of bearings, pistons, piston-rings, and gearwheels is time consuming and expensive. Gear lubrication is a significant concern in a wide range of industries which use power transmission. However, prototype testing of gear-boxes not always provides the necessary detail information for complex modern gears often carrying greater loads with high rotational speeds. CFD model prediction is thus an effective tool for optimization of oil flow around the rotating components in a gear-box. The results of CFD simulations can help to improve the efficiency of transmissions, reduce the friction between the gearwheels (pitting), minimize load-independent spin power losses, and assess oil splashing effects on gear housing. The newly enhanced Overset Mesh technology which allows for multiple overlapping overset zones in STAR-CCM+ coupled with multiphase flow based on the Volume of Fluid method (VOF) offers the necessary simulation environment for dealing with such complex simulation problems as rotating gear systems.

More information can be found in our publications.