Optimization of oil spray cooling on electrical machines

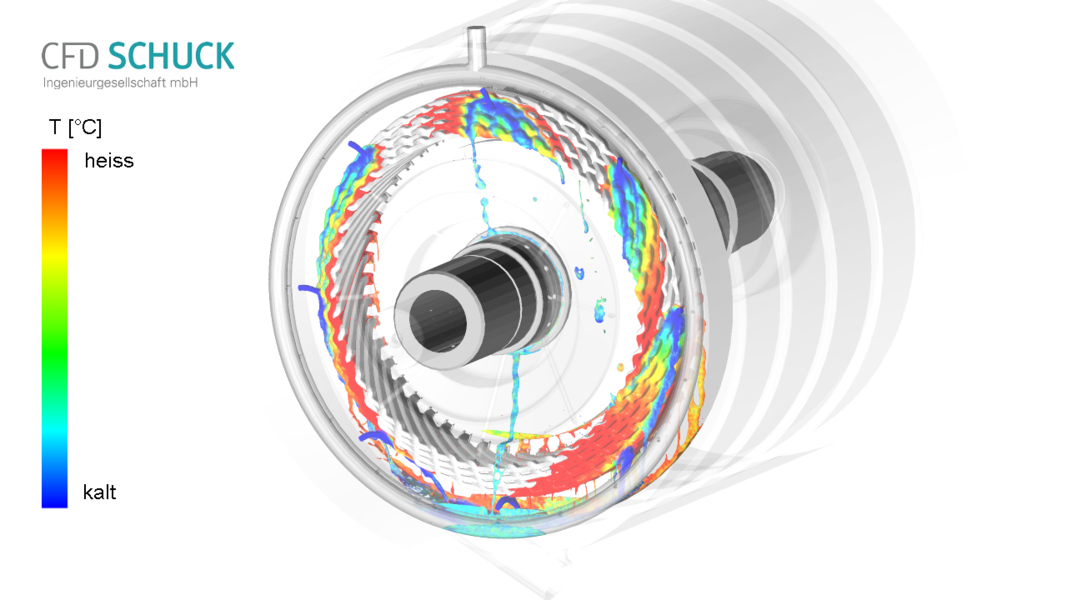

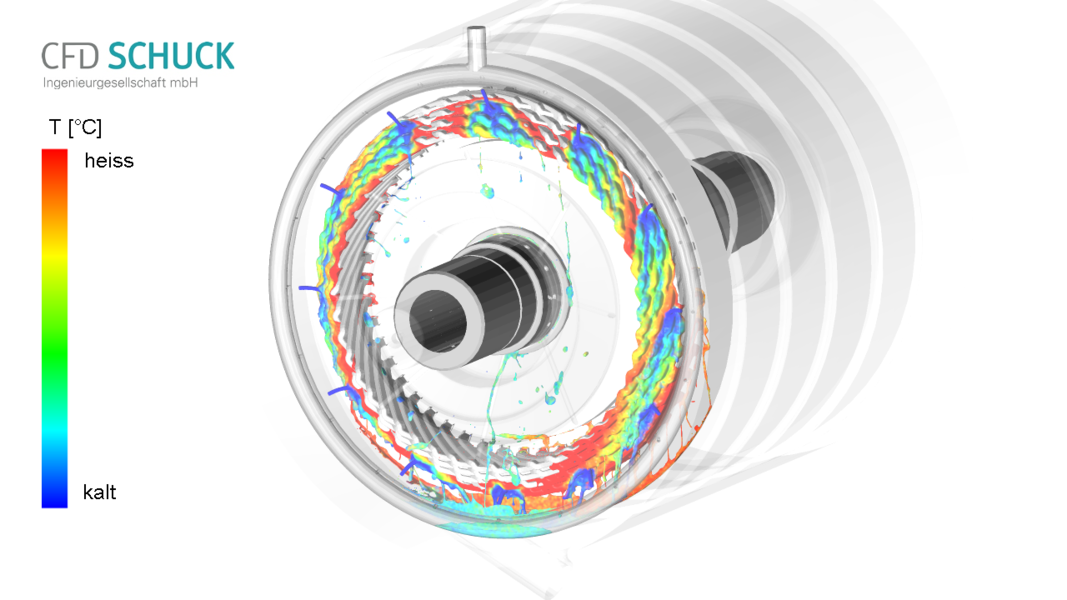

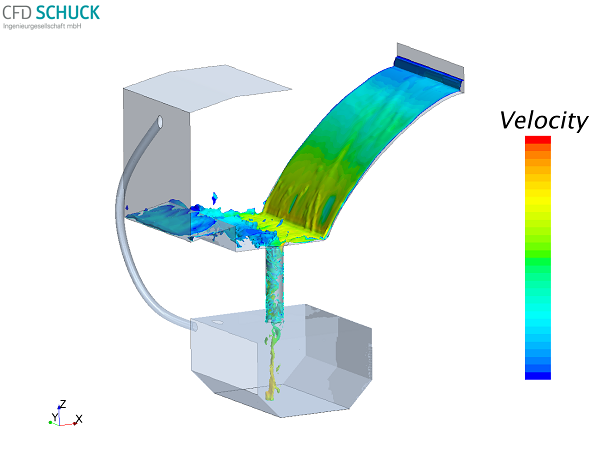

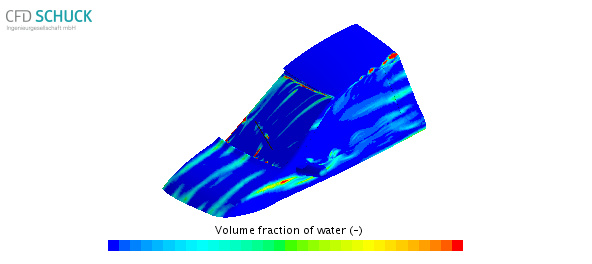

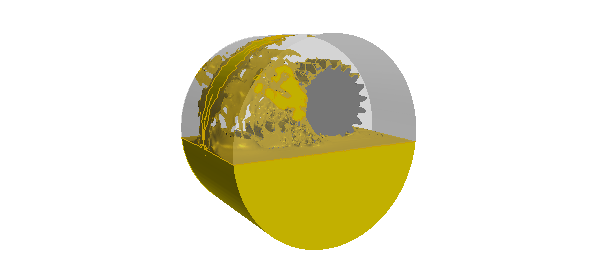

The cooling of electrical machines plays an important role in many questions. Modern simulation methods offer the possibility of designing cooling systems quickly and specifically for specific load cases. In the case of the oil spray cooling of a winding head, a method is now available that allows a quick and automated optimization by combining different software tools.

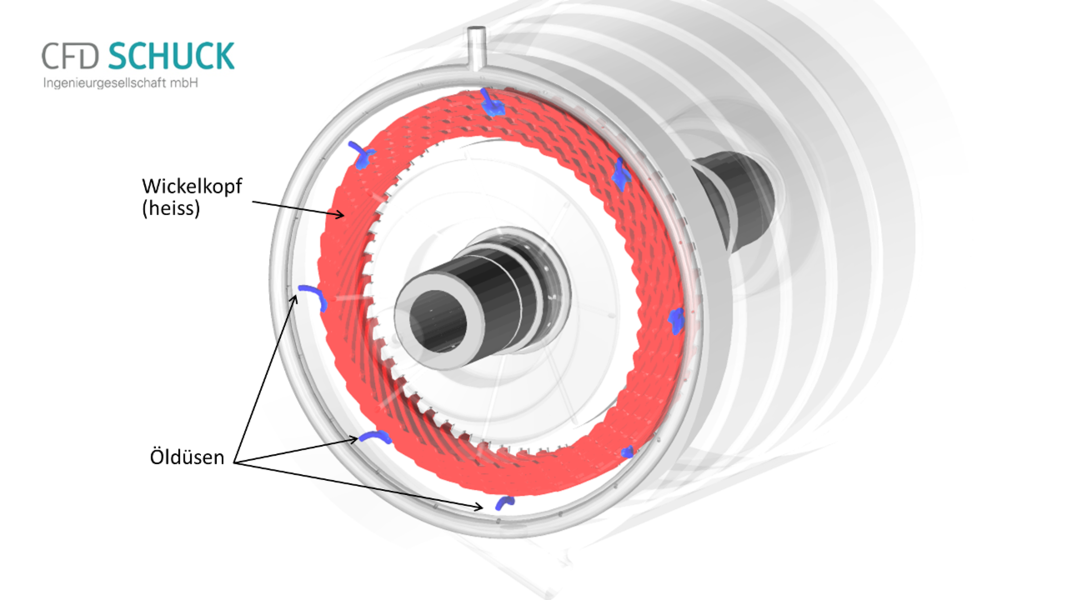

Optimization examines a variety of design options to determine a suitable configuration for good cooling . Typical design variables are the number and diameter of the nozzles, but also inclination and position relative to the winding head. Likewise, issues such as oil throughput or winding head temperature must also be assessed.

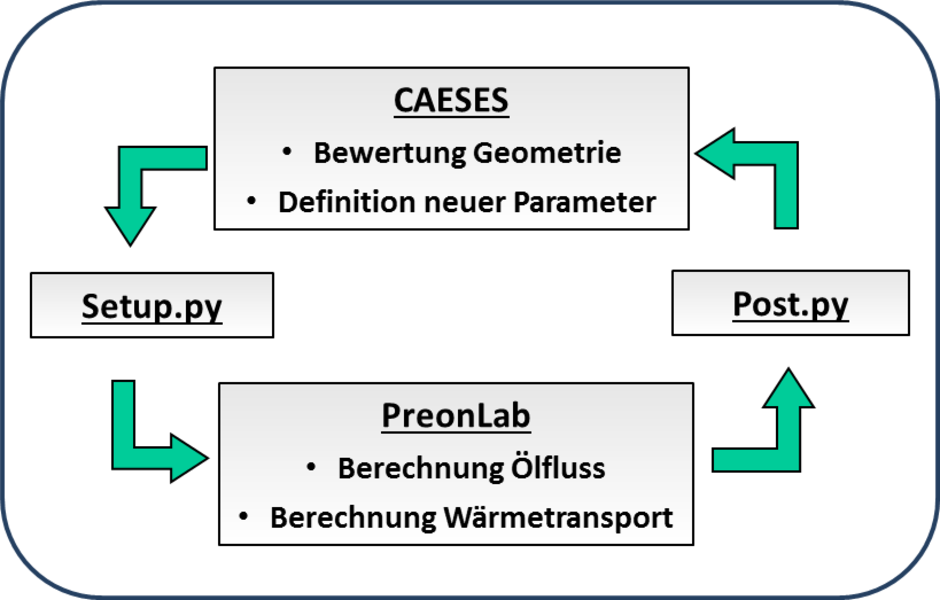

The SPH software PreonLab is used for CFD calculation of the oil spreading and cooling , the optimization is implemented with the software CAESES. In addition, Python routines are used for geometry generation, model setup, and evaluation. In our example (see video below) 40 design variants were examined in 3 days.

Further information can be found under spray cooling and SPH-Method. You can also contact us directly.